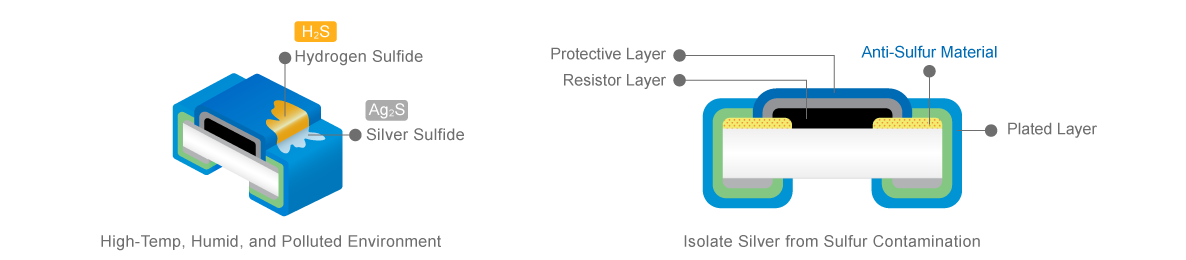

Exposure to sulfur dioxide causes a corrosive reaction when silver alloys encounter sulfur gasses or liquid. This typically decreases resistor conductivity and thus increases failure risks. SMART uses ASRs (Anti-Sulfur Resistors) when needed for SMART-built products, allowing them to operate reliably in harsh sulfur-rich environments to meet the highest industrial standards.

Why Anti-Sulfur Resistor?

Resistors use silver because of its conductivity and stability. Sulfurous environments have a negative impact on the resistors because sulfur easily reacts with silver (Ag), and creates silver sulfide (Ag2S). The silver starts to corrode in contact with sulfur. This corrosion lowers conductivity and can potentially lead to module failure.

How Does It Work?

To avoid a short circuit caused by silver sulfide, an extra protective layer is added around the electrode to effectively isolate the silver from direct air contact and potential sulfur contamination. In addition, SMART anti-sulfuration memory modules adopt Anti-Sulfur Resistors (ASRs) with a more resistant alloy, allowing them to operate reliably in harsh sulfur-rich environments to meet the highest industrial standards.