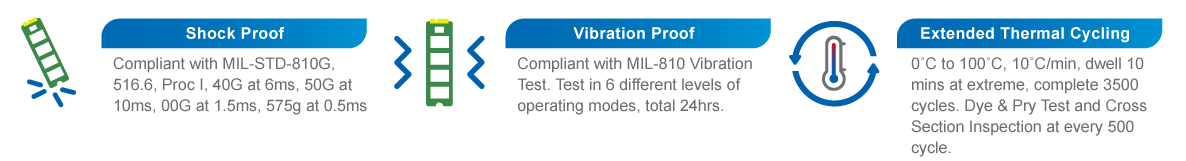

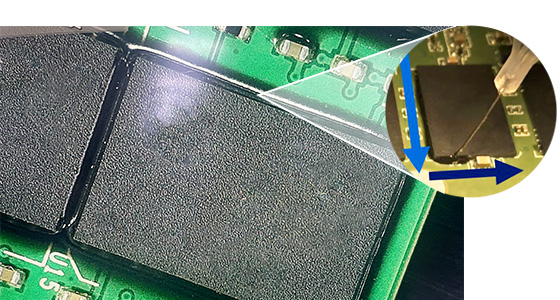

Underfill is a polymer or liquid epoxy that is applied underneath the perimeter of key components on a module to strengthen the solder joints and reinforce the product’s resistance against shock, vibratory stress, gravitational acceleration.

Why Underfill?

For harsh environments, such as in transportation, automotive, and industrial applications, BGAs are surface mount components that have difficulty meeting mechanical shock and substrate flexing tests. These packages are not designed to survive drop, bend and twist tests or shock and vibration tests.

How Does It Work?

Underfill provides a strong mechanical bond between BGA components and the circuit board in order to increase resistance against vibration and reduce thermal stress damage.

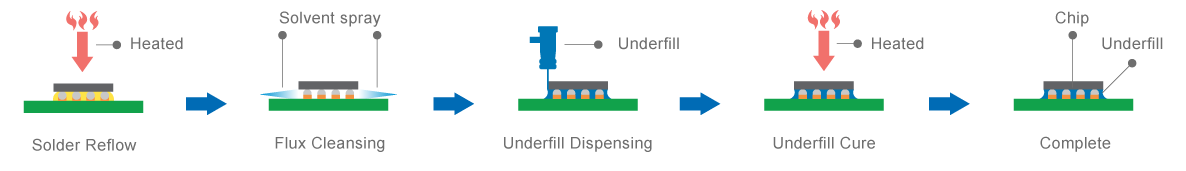

1. Flux dispensing: Dispense a controlled amount of flux material into a gap between a chip and the substrate.

2. Chip placement: Align the chip onto the substrate.

3. Solder reflow: Run the assembly through a reflow solder oven.

4. Flux cleansing: Remove the leftover flux residues.

5. Underfill dispensing: Dispense the underfill onto the substrate.

6. Underfill cure: Thermally cure the underfill in the oven.

SMART's DRAM Solutions with Underfill

SMART Modular Technologies’ memory modules with industrial temperature support and underfill capabilities provide a reliable solution for mission-critical applications. By enhancing reliability, performance, and environmental resilience, these modules enable the development of advanced, high-performance computing systems across various industries.